Operational and Predictive Intelligence from Camera to Dashboard

See More. Know More. Do More.

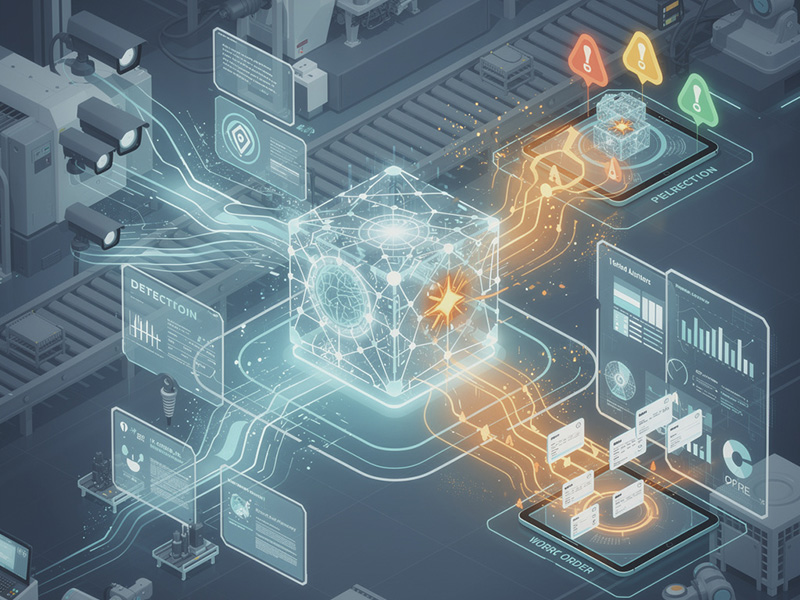

360.ai transforms industrial operations through real-time vision and predictive intelligence. By combining advanced monitoring, analytics, and automation, it helps manufacturers enhance efficiency, maintain quality, and prevent downtime.

- Customisable KPIs – Track performance in real time

- AI-Powered Insights – Detect issues before they impact output

- Smart Alerts – Stay informed and act instantly

capabilities

Unified Monitoring, Adaptive Intelligence, Instant Decisions

Deploy modules that see every product, anonymise every operator, and forecast every slowdown without forcing teams to change their tools or workflows.

Edge Connectors

Plug-and-play gateways send secure video within minutes, ready for edge or cloud analysis.

- Plug-and-play gateways live in minutes

- Edge or Cloud analysis with seamless switching

- Fits existing OT networks without disruption

Operations Graph

Live dashboards connect assets, lines, and teams so causes are easy to spot and sites are simple to compare.

- Every asset and line mapped as one connected graph

- Compare sites and shifts instantly via live dashboards

- Trace inefficiences with upstream/downstream links

Privacy-by-Design

Built-in privacy keeps context while hiding identities, helping deliver compliant video analytics.

- Automatic operator anonymisation with context preserved

- Compliance-ready video analytics built in

- Insights delivered without exposing identities

AI Inference

The platform turns detections into alerts, work orders, and reports that match each plant’s process.

- Turns detections into alerts, tasks, and actions

- Plant-specific rules filter noise and keep relevance

- Scales across sites with consistent accuracy

Predictive Intelligence

Adaptive models keep learning to predict downtime, yield shifts, and upcoming maintenance.

- Predicts downtime, failures, and yield shifts early

- Detects hidden patterns before issues escalate

- Enables proactive, not reactive, operations

Unified Dashboards

Clear, real-time factory insights through visual dashboards and natural language interaction, driving smarter decisions and performance.

- Real-time intelligence across the entire factory

- Natural-language queries for instant answers

- Compare shifts, lines, and global sites effortlessly

Simulations

Simulate what-if scenarios on the digital factory floor to identify bottlenecks and optimise staffing for peak production efficiency.

- Test digital what-if scenarios instantly

- Reveal bottlenecks before they hit production

- Optimise staffing, changeovers, and throughput

Automated Reports

Generate customisable, LLM-powered summaries that translate live metrics into executive-ready reports tailored to every stakeholder.

- AI-generated, stakeholder-ready summaries

- Converts metrics into clear narratives and KPIs

- Removes manual reporting – fast, accurate, consistent

proof & performance

Built for Industrial Excellence

360.ai accelerates productivity, reduces downtime, and maximises output across every stage of manufacturing. Backed by award-winning research and multi-patent IP, the platform unites real-time vision, analytics, and predictive maintenance to keep production lines running faster, smarter, and more efficiently.

- Predictive Maintenance – Detect and fix issues before they cause downtime

- Operational Efficiency – Streamline production cycles and boost plant performance

- Data-Driven Optimisation – Reduce scrap, improve quality, and increase profitability through continuous AI insights

industrial sites monitored

components analysed

Reporting time reduced

Detection Accuracy

Bring intelligent insights to your production lines

See how Industry 360 cuts defects, accelerates throughput, and keeps every audit ready.

Work with us

See how we can work with you on your next project…